Get advice

Contact VMI in your region

Select your

VMI Office:

VMI Holland BV | Head Office

- Gelriaweg 16

- 8161 RK Epe

- The Netherlands

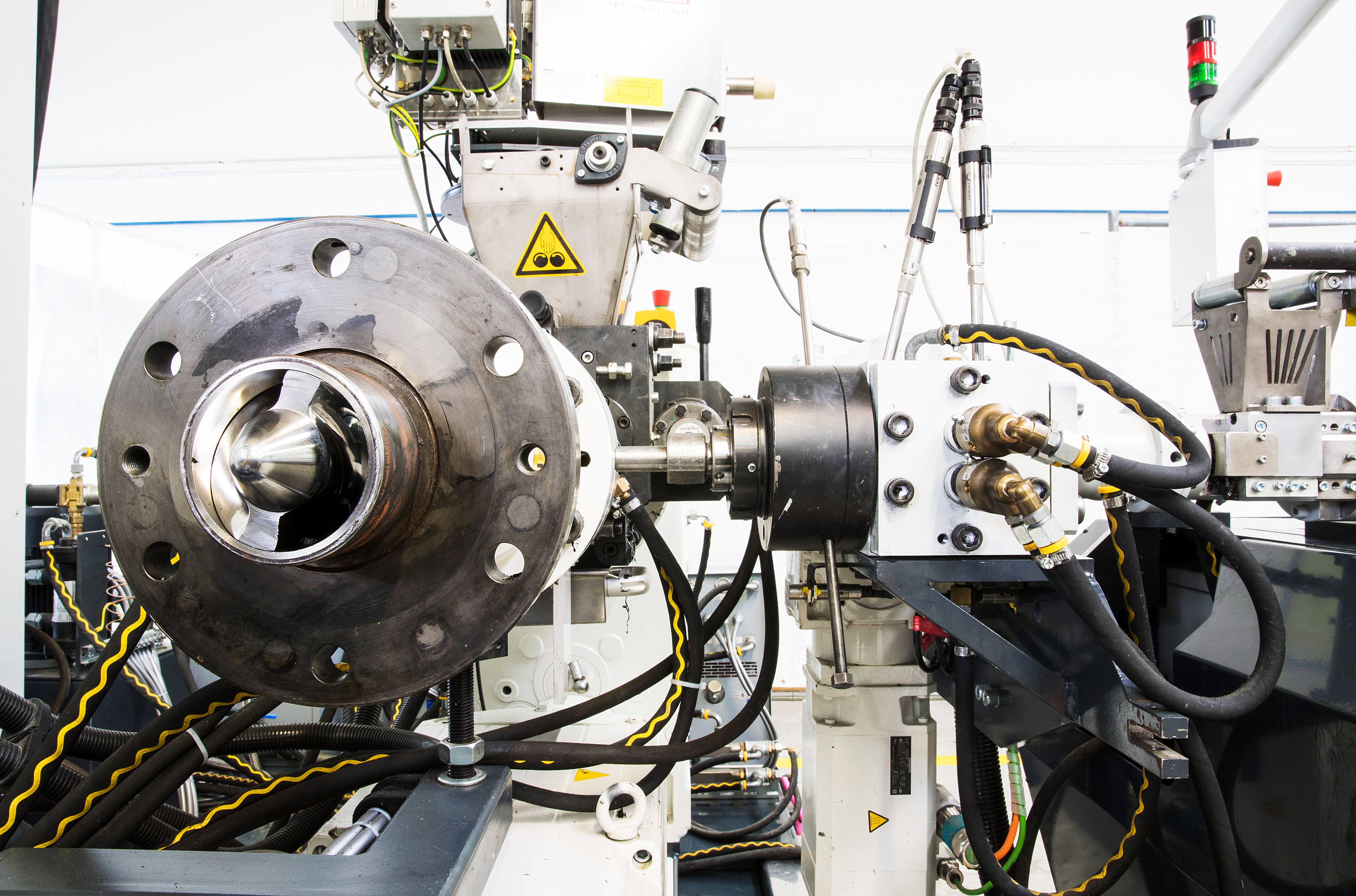

VMI Extruder gear pump systems are used for final mixing (iCOM technology) or for proportional blending of rubber compounds. The system provides you a high quality output, while saving costs on equipment investment and on energy use.

Using a VMI final mixing system opens up perspectives for final compound preparation outside of the traditional mixing room. The masterbatch compound can be transported without consideration for shelf life as there are no vulcanization chemicals yet. The final compound can be prepared at the production plant, with just the VMI final mixing extruder, and with integrated straining possibility.

Another possibility is the proportional blending of various rubber compounds. This gives you the possibility to be flexible in adjusting the properties of the final mix. Based on two different standardized compounds produced in an internal mixer, the final compound properties can be adjusted by simple changing of a parameter, changing the ratio of mixing the two base compounds into the final compound.

VMI Extruder gear pump solutions are based on the use of a special designed mixing extruder in combination with a gear pump. The main compound is fed directly into the main mixing extruder, in a strip form. Depending on the production requirements there are several options for dosing of the secondary materials. A dosing unit (Loss in Weight) can be used for granules, or an extruder gear pump combination can be used for a feed strip.

Since the final mixing process can now take place at the production site and just-in-time, there is no more need for long storage or transportation times, the rubber compound recipe can now be adjusted and fine-tuned towards optimal performance and lowest production costs.

Contact VMI in your region