Get advice

Contact VMI in your region

Select your

VMI Office:

VMI Holland BV | Head Office

- Gelriaweg 16

- 8161 RK Epe

- The Netherlands

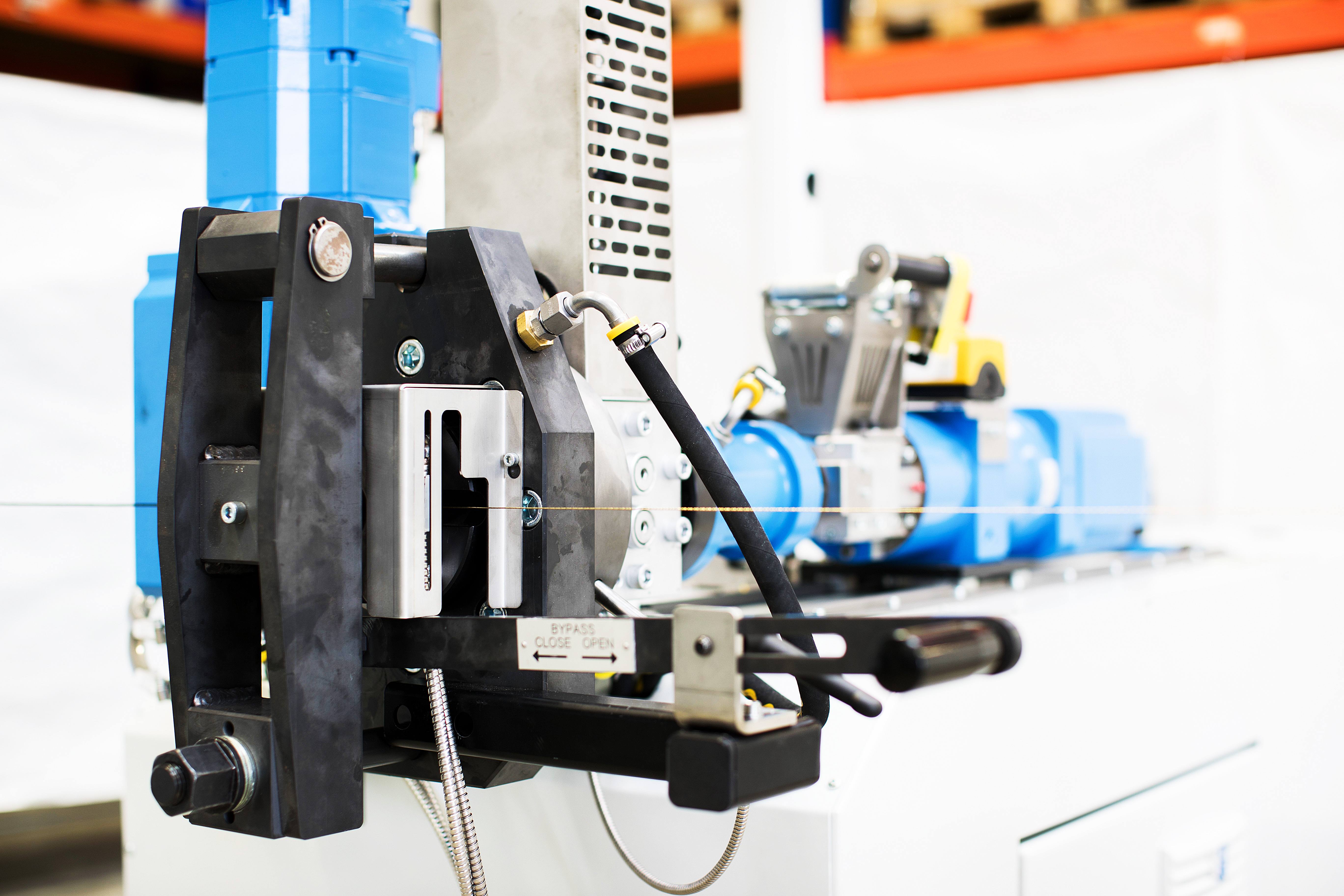

Precision of the extrusion product is an important requirement in many extrusion applications. VMI’s extruder gear pump systems combine the plasticization of an extruder with the accurate, high pressure volumetric output of a gear pump. You control compound plasticization and output pressure independently to ensure high accuracy and output, while preventing scorching.

The extruder gear pump systems of VMI are built to be fitted with a variety of extrusion heads to meet your specific requirements. We offer extrusion heads for profile extrusion and straining or a cross head for tube covering or for belt strip extrusion. In case the extrusion system is placed in front of a salt bath or hot air line, the configuration could also include a vacuum screw and barrel set up. The modular range of small and large scale extruder gear pump systems makes it possible to select the right configuration for each situation.

The linear gear pump technology and precise output characteristics decrease extrusion tolerances and realize a significant reduction of the scrap rate. Additionally, the linear output behavior of the gear pump enables predictable line speeds of the extrusion system and an easy integration with the downstream equipment. This is not only the case for a continuous run, but also in startup and slow down, a perfect calibration between the extrusion system and the downstream line is obtained.

To accommodate a large range of materials and applications, there are many different designs available for the screw and barrel. From standard conveying designs for maximum machine output to PIN screws and various mixing designs.

VMI is specialized in integrated extruder gear pump systems, where the extruder takes care of plasticizing the rubber compound and feeding the material into the gear pump. The gear pump ensures the accurate and continuous output, also in the case of high output pressures.

An extruder is basically a screw that is rotating within a barrel. The screw is rotating and pushes (pumps) the rubber compound towards the output side of the barrel. On the input (feeding) side, a strip of rubber compound is pulled into the extruder. The rubber strip is clamped between the feedroll that counter-rotates to the screw and the extruder screw and gets pulled into the extruder.

The gear pump contains a set of intermeshing gearwheels and the compound is transported from input side of the pump to the output side, but cannot go back due to the tight intermeshing of the teeth on the gearwheels. As the volume is fixed by the size of the gearwheels, the precise output of the machine can be controlled by the rotation speed (rpm) of the gearwheels.

Following the gear pump the material then flows through the extrusion head. A filter can be inserted in the head to separate large particles (or contamination). The clean material flows through the filter to the output. The material flows through a die at the final stage in the head. The die has an opening designed to shape the material according to the product requirement.

Continuous high accurate pelletizing is achieved by adding a VMI pelletizer cutter to a VMI extruder gear pump system. The volumetric operating gear pump in combination with the continuous rotating pelletizer knife provides high output and high accuracy. This results in very precise cut of rubber pellets, which are used for feeding other extrusion systems.

Degassing of your rubber compound with a VMI vacuum extruder screw is common use to prevent porosity in your rubber material. The vacuum screw and barrel are designed to allow degassing moisture or other volatile substances of the compound that could get gaseous during mixing. The vacuum system extracts the steam after the rubber is heated. The screw delivers the rubber, free of entrapped air, to the gear pump at an adjustable inlet pressure.

Contact VMI in your region