Cleaner operations, better conditions

Cutting pollution while improving efficiency.

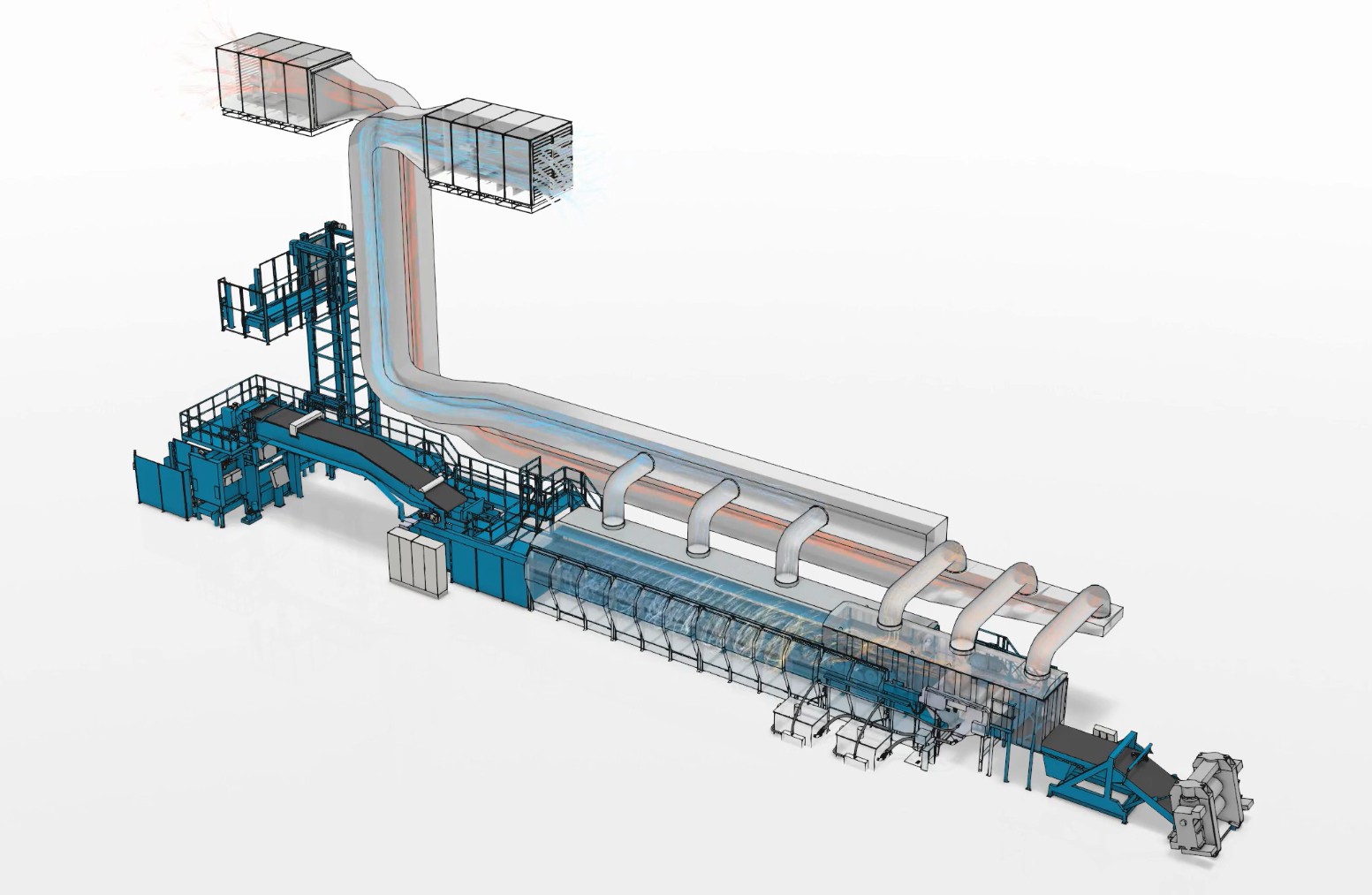

Batch-Offs do a simple but essential job in any rubber plant, by cooling the rubber strip or slab produced in the mixing room until it can be safely moved into storage. The cooling process is also simple: air is circulated around the hot rubber at ambient temperature- and the heat is dissipated into the air.

So far so simple. But here’s the potential issue. Conventional Batch-Offs use the most basic form of air circulation.

- Air is blown into the cooling rack where the rubber slab or strip has been placed- with the air coming directly from the immediate environment. That normally means from the factory itself, and the air is then blown right back into the factory again after circulation.

- Heat is dissipated, but not that efficiently and the air, now filled with particles, simply goes into the neighbourhood, with workers in the factory being exposed to pollution first and everyone else in the area exposed next.

- Energy is needed- lots of it- in two areas. First: to power the mixer and all other downstream equipment, itself, which creates heat, and second: to power the cool air blowers, to remove heat.

That’s inefficient and costly, as well as being dirty.

VMI’s advanced new Batch-Off technology reduces pollution, while improving sustainability and working conditions.

- Automation reduces human touch points and drives much better operational efficiency (click here to read our Pendulum Stacker automation blog).

- VMI’s Closed Air Circulation solution improves working conditions and meets environmental requirements more effectively.

- In addition, the new system could even capture some of the heat from the cooling rack to use for other purposes- and that might reduce overall costs.

Closed Air Circulation delivers all these benefits:

- Air circulates only in the cooling rack, powered by integrated air treatment units, which keep polluted air separate from the rest of the plant. That improves the ambient environment for the people working there.

- Air can optionally be reused until its temperature has reached the point where it cannot remove heat anymore, which can reduce energy costs.

- Air is not released into the environment until it has been filtered to remove potentially harmful particles and odours, which therefore meets environmental standards and ensures full compliance- all with no additional investment.

- Perhaps more radical is the potential for capturing heat and reusing it. Though this requires specialised equipment, the advantages could be significant, as it means the wasteful process of heating followed by cooling, then heating again can be made more efficient, with captured heat fed back into other processes.

VMI is proving that the most basic of all rubber processes- cooling the produced compounds- can be significantly enhanced through technology innovation.

The world runs on rubber. The rubber industry depends on more advanced and high-performing compounds, and rubber producers need to make their processes faster, more accurate and efficient than ever. At VMI, helping the rubber industry set new standards and become more profitable is our mission.

To find out more, contact our team via the form below or follow us on LinkedIN

Contact form

![]()