The whole world depends on rubber components, with important uses in almost every industry. Extruded rubber is used to make:

Every home contains extruded rubber, every vehicle runs on rubber tires, almost every product depends on rubber components that work to precise tolerances and are produced at high speed, often for extremely low cost.

These days there is another level of complexity at work. As uses become more varied and demanding, the rubber components used by manufacturers are changing. They need different characteristics, different tolerances, different chemical profiles…

That’s another reason why Precision Extrusion technology from VMI is now strategically vital for so many different manufacturers.

The Precision Extrusion breakthrough

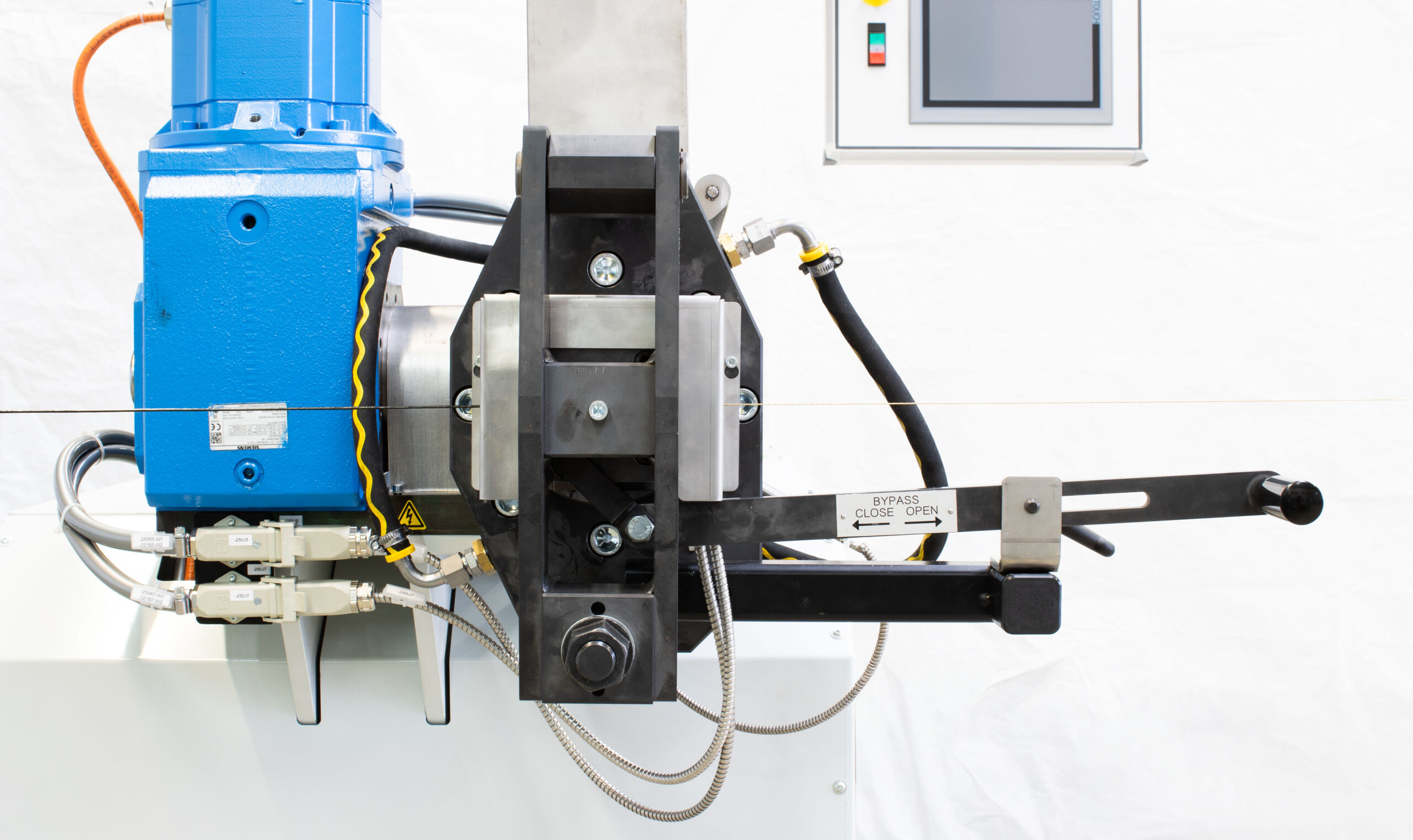

VMI developed a technique to combine continuous extrusion and gear pumps years ago: it is now successfully used for creating rubber-based components made to very demanding specifications and has become an essential component for production processes in many different industries.

We have adapted the same technique for tire building, both for “all-in-one” single cell manufacture and, increasingly, for hybrid solutions, which blend conventional tire building machines with Extrusion to make both carcass and tread in a more efficient, integrated process.

This approach offers much greater flexibility, enabling manufacturers to build a complete tire, from mixing the compound to making the steel wire framework to delivering many different kinds of tread, without needing huge production runs of the same specification to make a profit.

This potential revolution in tire making owes a great deal to VMI Precision Extrusion technology, which was initially developed for general use in the technical rubber industry. This technique has now been refined and improved to meet the demands of automated tire building, while VMI is also extending our enhanced Extrusion solution into a growing range of other industries- where it is driving a quiet revolution in efficiency and profitability.

Integrating Continuous Extrusion with Tire Building

VMI’s continuous extrusion technology is proven to reduce energy use, cut operating costs and improve environmental performance in most industries and for most purposes, and the tire industry is one of the most important examples. Precision Extrusion makes Tire manufacturing much more flexible because it reduces dependence on mass produced components, which are taken from stock and not always available in the exact material, quality or sizes required.

Precision Extrusion enables designers to control the entire production process with greater accuracy, leading to components and finished assemblies that are more exact in shape and size, are built faster, using less energy, leading to greatly reduced levels of waste and scrap.

In Tire building, this means building in a “batch of one”, where the precise specification can change, not only between batches, but between individual products. For other industries, as well, the ability to specify the exact form and size of each component can have a transformational impact on both quality and operational efficiency.

A profitable new reality

VMI’s Precision Extrusion technology is now a mature, proven factor in rubber production. It simplifies and shortens processes by removing the need to extrude a batch of compound, which may then need to be stored, retrieved and reheated in a separate production stage. This is the key benefit of VMI’s integrated Continuous Mixing– or iCOM process.

iCOM transforms the final stage of rubber compound mixing, where curing chemicals are incorporated into the compound. Although the rubber industry has used internal mixers for a long time, the final mixing stage has to be managed with the greatest care, using a more gentle approach. iCOM delivers exactly the right outcomes for this stage and is extremely easy to install, as it only requires a flat floorspace for the production area.

Continuous Extrusion enables manufacturers to eliminate a complete production stage, reduce the need for storage, cut energy costs and improve product quality. This is a potential technology breakthrough- not just for tire building but right across the rubber industry.

In addition, our advanced software management solution makes it extremely easy to control production with outstanding flexibility. Changing specifications, even in fairly radical ways, is now managed through simple commands using an intuitive interface- with no engineering work required. The sheer simplicity of the system is a vital factor in the productivity improvements VMI can now deliver.

For your own personalized introduction to precision extrusion in rubber, fill out the form below or connect with us on LinkedIN and we will set up a deep dive into the technology, how it works and what it means in the context of your own business.

![]()