- Detailed machine performance information, but reduced paperwork and reporting

- Reduced maintenance downtime of machines

- Guides your maintenance crew to optimize output and quality

- Continuous stable production flow

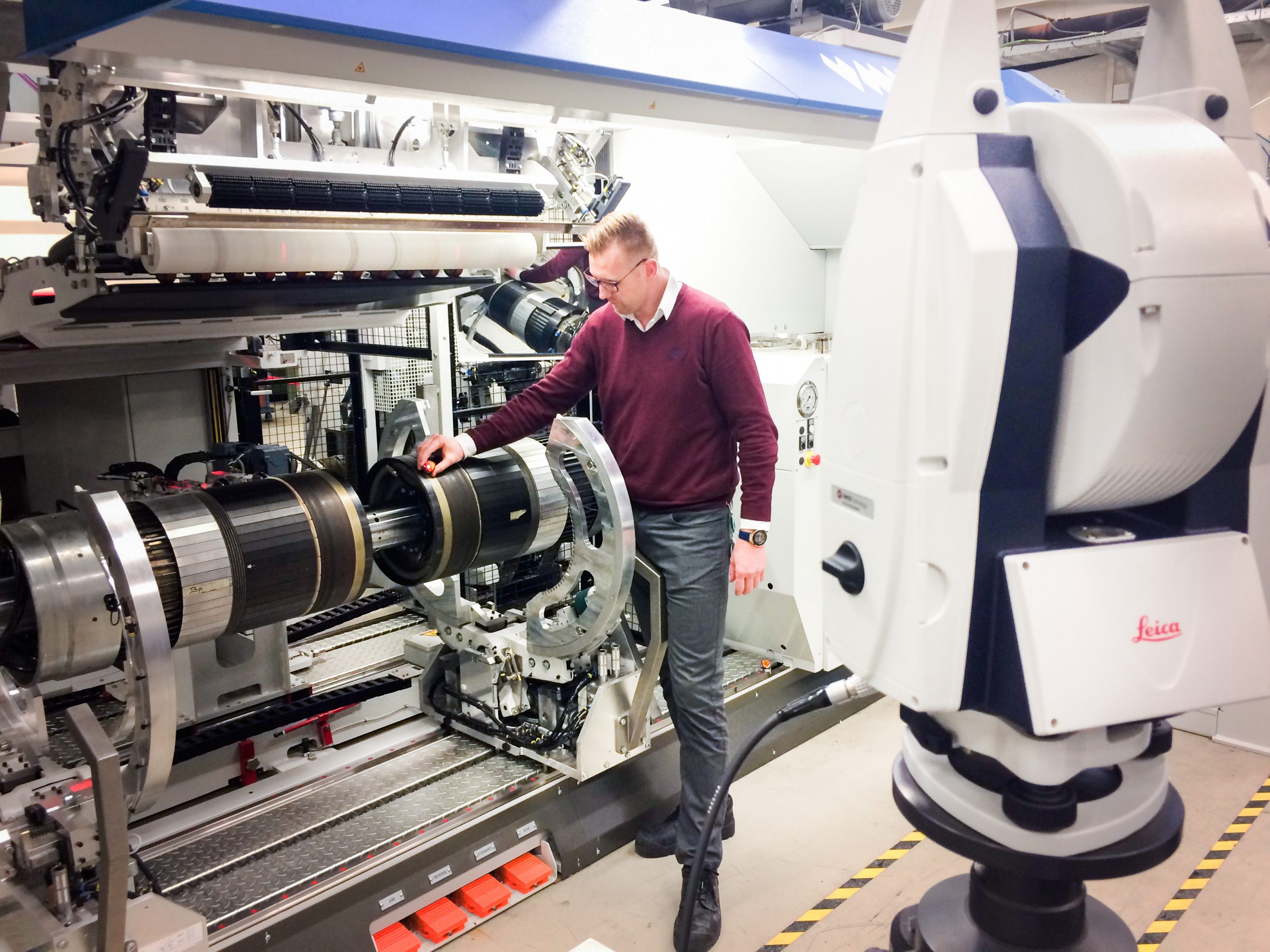

No-one likes to be burdened with paperwork and reporting, but up to date instant insight in the performance of your equipment allows you to optimally control your processes. That is why VMI has developed various Management Support Tools to make the task of ordering spares, or executing alignment checks as simple as possible. VMI’s management support tools furthermore give you the information you need to make sure your equipment performs up to standard. It also forms the basis of potential improvement projects for process optimization.

By making use of these easy to use tools, which can be customized to your requirements and machine specific details, you reduce maintenance downtime and lessen the time your technicians spend on non-core activities. It furthermore provides a real-time insight in your actual OEE percentage. The result: a continuous production flow with less scrap, fewer unexpected stoppages and an excellent end product quality.

The tools and their relevant reports are created based on industry standards, allowing you to share them directly with your customers as proof that your procedures are in place and that important activities are executed properly.