Helping to automate every part of the rubber process.

Conventional batch-offs are comparatively simple items. They store and cool the hot rubber compounds that come from the upstream mixer to the point where they can be moved to storage, ready for shipping to customers.

As production plants and warehouses become more automated, the question is: can we rethink and redesign the batch-off to help deliver end to end automation? That’s the key to cutting energy use, costs, waste- boosting profitability and eliminating errors.

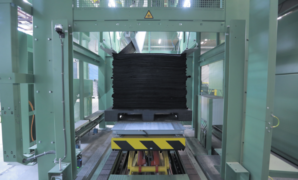

VMI’s pendulum type stacker brings technology into the new world of automated operation, in which human touch points are drastically reduced and every stage of the process is integrated, simplified and made much more efficient and error-free than before.

Here’s how it works:

High throughput: the stacker can handle up to 20 tonnes of product per hour if needed, enabling it to cope with modern, high performance mixing lines. It will handle the finished materials and prepare it for cutting, shaping and storing at high speed.

Traceability: every batch is coded for tracking purposes, which means that any variations in materials can be instantly identified, down to the precise item in a specific location, from mixer to truck.

Automated sampling: along with traceability, the VMI system means samples can be taken non-intrusively at regular points in the process, rapidly tested on site and any discrepancies identified for intervention at once. This is no longer an historical issue, with results coming way after the material has been taken from the batch-off, as this is now all done in real time, on the factory floor.

The VMI hugger belt system: this can optionally be added to the batch-off, which can then automatically transfer rubber compounds from batch-off level back to mixer level for second stage mixing- without operator intervention. The system always knows where to send the rubber slab, so it is moved to the right place automatically.

Logistics and storage: most large rubber plants are now automated for movement, storing, picking and packing, with Automated Guided Vehicles (AGVs) moving pallets to high bay storage racks, ready for shipping to customers. Although some conventional forklift trucks are in operation, these different stages are normally executed without direct intervention by human operators. In fact, high bay storage is only practicable through automated handling.

So how does the VMI Pendulum type Stacker make a difference?

VMI has been an early mover and global leader in automation for 80 years now, and its Pendulum type stacker extends the benefits of automation right through to the point of sale. VMI’s advanced, best practice software enables full integration with all other management systems on site, which is the key to end-to-end automation, and adds value in all the areas that matter most.

Fast on-site sampling, full traceability and slab cutting, together with integrated handling and logistics- these are the keys to higher operational efficiency, greater flexibility, accelerated production, elimination of errors and lower costs.

The world runs on rubber. The rubber industry depends on more advanced and high-performing compounds, and rubber producers need to make their processes faster, more accurate and efficient than ever.

At VMI, helping the rubber industry set new standards and become more successful through innovative technology is our mission.

To find out more, fill out the form below to set up a meeting or connect with our team on LinkedIN.

![]()

Contact form